The Importance of the Main Frame in the HP300 Multi-cylinder Hydraulic Cone Crusher

In the demanding realms of mining and aggregate processing, machinery durability is not just an advantage—it is a necessity. The HP300 Multi-cylinder Hydraulic Cone Crusher exemplifies this principle, with its main frame serving as the cornerstone of its exceptional longevity. Engineered to endure operational stresses for 10 to 20 years, the main frame’s robustness ensures reliability, efficiency, and cost-effectiveness, making HP300 Multi-cylinder Hydraulic Cone Crusher a pivotal innovation in industrial crushing technology.

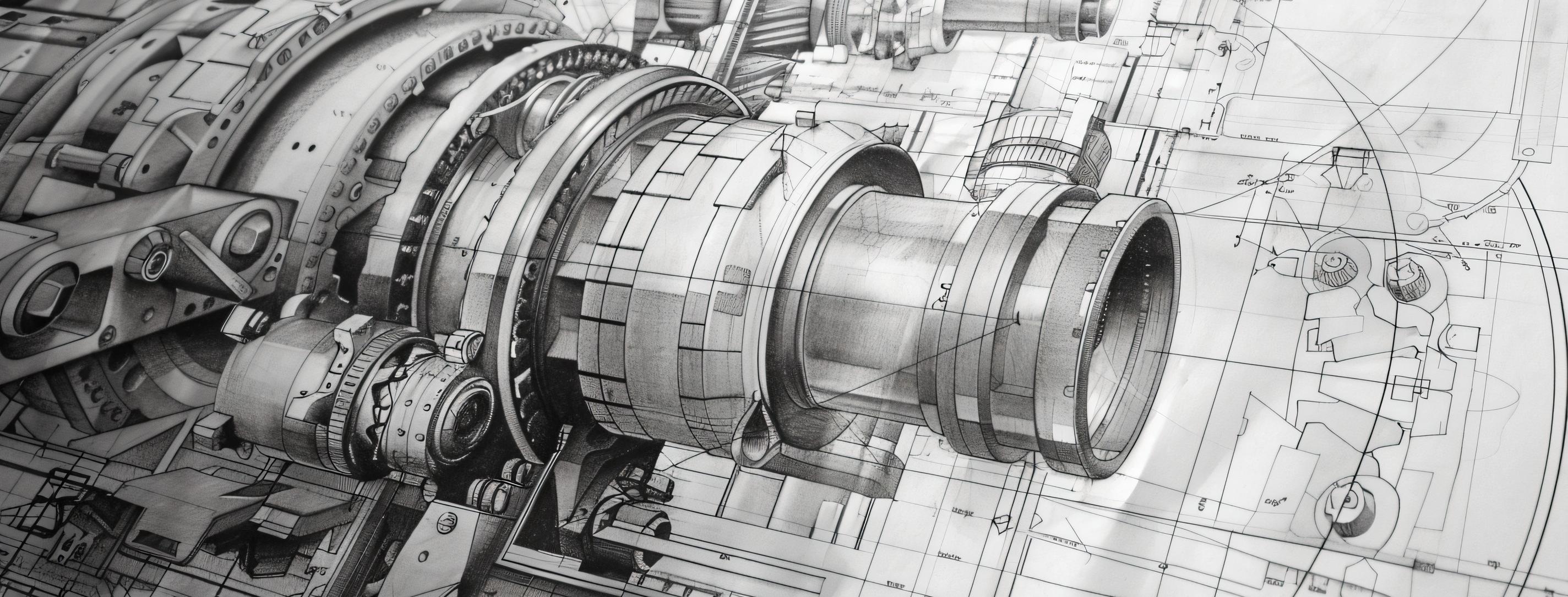

Materials and Construction Excellence

The HP300 Multi-cylinder Hydraulic Cone Crusher’s main frame is constructed from high-strength alloy steel, meticulously selected for its resistance to wear and fatigue. Advanced manufacturing techniques, such as precision casting and automated welding, eliminate structural weaknesses, ensuring uniformity and integrity. Post-weld heat treatments further enhance durability, mitigating stress concentrations that could lead to cracks. This meticulous construction transforms the main frame into an unyielding backbone, capable of withstanding decades of high-impact crushing forces.

Optimized Design for Stress Distribution

The main frame’s geometry is optimized to distribute mechanical stresses evenly. Reinforced ribs and contoured surfaces redirect crushing forces away from vulnerable points, preventing localized wear. This design of main frame philosophy not only prolongs the main frame’s lifespan but also safeguards internal components like the eccentric assembly and liners, reducing maintenance needs. By absorbing and dispersing energy, the main frame maintains operational stability even under extreme loads.

Synergy with Hydraulic Systems

The HP300 Multi-cylinder Hydraulic Cone Crusher integrates a multi-cylinder hydraulic system directly into the main frame, enabling real-time adjustments to crushing parameters. The main frame’s rigidity ensures precise alignment of hydraulic components, minimizing vibrations and misalignment-induced wear. This synergy enhances efficiency, allowing the HP300 to adapt to varying material hardness without compromising structural integrity.

Economic and Environmental Benefits

A service life spanning decades translates to significant cost savings. Reduced downtime for replacements and repairs maximizes productivity, while lower long-term capital expenditures improve ROI. Environmentally, the extended lifespan diminishes waste generation and resource consumption, aligning with sustainable industrial practices.

Conclusion

The HP300 Multi-cylinder Hydraulic Cone Crusher’s main frame is a marvel of engineering, combining advanced materials, intelligent design, and hydraulic integration to redefine durability. The main frame's ability to endure harsh conditions for 10–20 years underscores its role as the crusher’s foundation, offering industries a reliable, cost-effective solution that balances performance with sustainability. In an era where efficiency and environmental responsibility are paramount, the HP300’s main frame stands as a testament to enduring quality.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/