Shanghai Zhuyan's Cone Crusher Spare Parts: Precision-Engineered for 10-20 Year Lifespan in Global Mining Operations

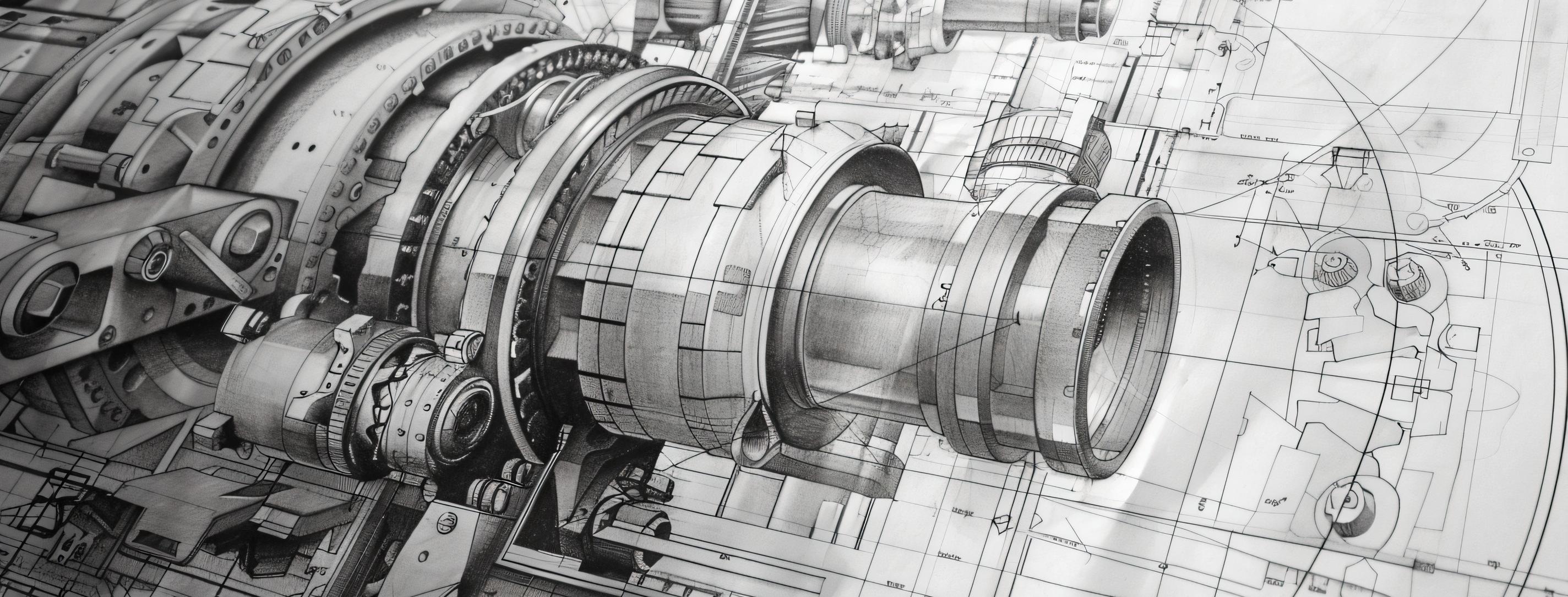

The spindle cone assembly for the CH870 single-cylinder cone crusher has completed precision machining at Shanghai Zhuyan Heavy Industry and is prepared for overseas shipment. As the core component of cone crushers, this assembly combines 23 precision-machined elements including the main shaft, cone bushing, and thrust bearing housing. Manufactured from high-strength alloy steel castings, our cone crusher spare parts undergo five-axis CNC milling to achieve critical surface tolerances within ±0.01mm. The thermal shrink-fit process, assisted by laser alignment systems, ensures concentricity errors below 0.005mm - a testament to the extended service life of the spare parts, which typically operate 10-20 years in demanding mineral processing environments.

During production, our ISO 9001-certified quality system conducted three-phase inspections using coordinate measuring machines (CMM), verifying 12 critical parameters from cone base flatness to main shaft perpendicularity. The surface carburizing-quenching treatment enhances wear resistance, achieving HRC62-64 hardness - a key factor enabling Shanghai Zhuyan's cone crusher spare parts to maintain optimal performance through decade-long operational cycles. Post-machining verification included 48-hour continuous no-load test runs, confirming vibration levels within 2.5mm/s RMS specifications.

The packaging solution reflects our commitment to preserving cone crusher spare parts' longevity during transit. Custom-built wooden crates incorporate vacuum-sealed moisture barriers, 3D shock-absorbing brackets, and humidity indicator cards. The exterior IP67-rated protective coating withstands marine salt spray corrosion, ensuring these durable cone crusher spare parts arrive in pristine condition. The shipment will depart Shanghai Port via 40-foot high-cube containers, with estimated 30-day transit to destination.

Accompanying documentation includes ASME-certified quality certificates, installation blueprints, and 3D scan inspection reports. Notably, all cone crusher spare parts supplied by Shanghai Zhuyan Heavy Industry carry a unique lifecycle tracking code, enabling predictive maintenance scheduling to maximize their 10-20 year service potential. Our field engineers will provide on-site commissioning support, implementing proprietary alignment techniques that synergize with the extended durability of these premium cone crusher spare parts.

This delivery underscores Shanghai Zhuyan's leadership in manufacturing high-wear components for mineral processing equipment. Through optimized metallurgical formulations and stress-relief annealing processes, our cone crusher spare parts achieve 35% longer service intervals compared to industry averages. Clients benefit from reduced downtime and replacement costs, with documented cases of our cone crusher spare parts maintaining ssshhh90% original dimensions after 15,000 operational hours in copper ore crushing applications.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/